Design Characteristics

-The X-axis and Z-axis are all made of granite material, which does not require aging treatment, has no internal stress, and the overall straightness is less than 5um, effectively ensuring the high-precision requirements of the measuring machine.

-The Y-axis is made of silicon carbide ceramic material, which is lightweight and has good rigidity, ensuring high precision and stability.

-The three-axis guide rails all use double linear guide rails, which do not require an air source and can ensure operation in harsh temperature environments.

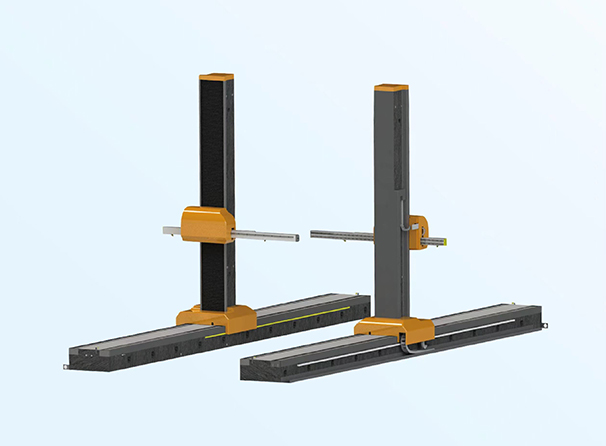

-Adopting an open structure, it facilitates the loading and unloading of workpieces.

-Using a heavy hammer balance, the balance slider has a dedicated track, without any impact or jamming.

-All three axes are equipped with 6-level precision German gear and rack transmission, ensuring smooth and noise free operation with no backlash during reverse operation.

-The three axes are all fixed with a British Renishaw single-end grating ruler, with the other end freely extending and retracting. The temperature of the grating ruler is not affected by the guide rail and is consistent with the temperature changes of the workpiece, ensuring the stability of machine accuracy.

-Linear temperature compensation technology for optional machines and workpieces can ensure measurement accuracy over a wider temperature range (16-24 ° C).

-All three axes are equipped with a British Renishaw coordinate dedicated controller, which is compatible with the measuring head and integrates 21 error compensations internally.